Culture | October 5th, 2016

By Chuck Solly

Photo by Chuck Solly

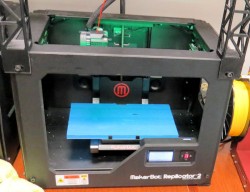

The geeks love this headline. 3D printing allows your imagination to run wild, provided you have the computer savvy and computer software to control the printer.

3D Printing began in 1984 with the Fused Deposition Modelling (FDM) printer invented by Stratasys.

The original printers were limited to plastics, but since then, suppliers large and small have developed techniques to print with a variety of materials and solve new use problems, each furthering 3D printing’s capabilities.

The 3D printing process works well for building small plastic parts a few at a time. Prototype builders have embraced this technology with both arms because of the low cost of both the machine and the raw materials. My example part is about 1 ¼ inches in diameter and 1 inch high.

Declining printer prices and the availability of component technologies have accelerated hardware innovation and expanded the market for 3D printing. Prices that started at about the quarter million dollar level and now are available on Amazon for as little as $265.

Software suppliers are developing standardized modeling tools because the older CAD (computer-aided design) tools were not built with 3D printing techniques in mind.

For individuals or organizations without the skills or available capital there are service bureaus that enable them to explore the technology and launch different business models. Service bureaus help customers by outsourcing the end-to-end 3D print production process.

There are several service bureaus right here in Fargo with the ability to produce your little plastic can opener.

Without using the service bureau, be prepared to buy and learn a CAD program, convert your design into a computer file that the 3D printer can understand, and then send it to the service bureau. They can then produce a small quantity of your part.

The technical challenges of correctly producing the part within tolerances can be daunting. But once the part is correctly produced and tested, the traditional manufacturing techniques can be used to produce a larger quantities. I’ll try to go into some of these other techniques at a later date if there is interest.

Rapid Prototyping is a related topic that I will just mention here in passing:

Rapid Prototyping has also been referred to as solid free-form manufacturing, computer automated manufacturing, and layered manufacturing. RP models can be used to create male models for tooling, such as silicone rubber molds and investment casts. In some cases, the RP part can be the final part, but typically the RP material is not strong or accurate enough.

Layered manufacturing means (typically) that a laser is used to harden a thin layer of plastic, one layer on top of another until a part is formed. This technology has morphed into many different processes most of which would require pages to explain.

Dr. David Wells at NDSU has been the point man for these manufacturing techniques here in Fargo. His students have been working on these related technologies for many years.

February 16th 2026

February 13th 2026

January 15th 2026

January 15th 2026

December 18th 2025

_(1)_(1)_(1)_(1)_(1)__293px-wide.jpg)

_(1)_(1)_(1)_(1)_(1)__293px-wide.jpg)